Duplex Coating

What is a Duplex Coating?

You may wonder why anyone would want to paint over a perfectly good galvanized coating. People do paint over galvanized steel on a regular basis though and for a wide variety of purposes. The reasons behind the decisions to do so range from financial to simply needing a color other than gray or silver while still maintaining the excellent corrosion protection that hot-dip galvanized coatings provide.

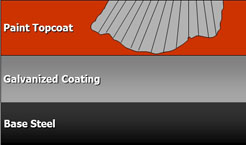

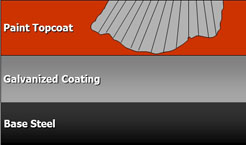

When paint is applied as a topcoat to a galvanized coating, the combination of the two protective systems is then termed a “duplex coating”. This duplex system provides a more sophisticated manner of corrosion protection. When steel that has only been painted corrodes, rust grows under the paint and eventually causes the paint to peel.

One of the most frequent reasons for paint failure is discontinuities in the coating. When a barrier protection (paint) is used alone, rust begins forming as soon as the barrier is breached. A galvanized coating under a paint system will eliminate early rusting at damaged areas. This mutually beneficial system increases the overall life of the product. The galvanized coating protects the base steel, supplying cathodic and barrier protection so rust will not grow and paint will not peel up. Paint in turn grants barrier protection to the galvanized coating. The paint slows down the rate at which the zinc is consumed, greatly extending the life of the galvanized steel.

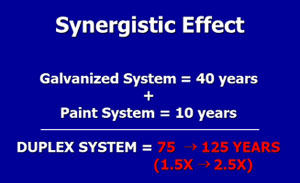

Synergistic Effect

Duplex system typically provide corrosion protection 1.5 to 2.5 times longer than the sum of the lifetimes of zinc and paint used individually. This characteristic is referred to as the Synergistic Effect.

The extended corrosion resistance is the most obvious, and most important, reason for using a duplex system. Because duplex systems greatly extend the service life of a product, maintenance costs are significantly decreased. Additionally, a product that lasts longer before it must be replaced will decrease the overall life-cycle cost. No single corrosion protection system can match the corrosion resistance afforded for most applications by painting over hot-dip galvanized steel.

Aesthetics

While galvanized coatings have an attractive gray metallic appearance suitable for a multitude of applications, painting the galvanized coating provides an alternative aesthetic appearance. For example, galvanized parts can be painted to match a specific environment, such as at a stadium, a theme park, or natural habitat. Painting over galvanized steel can also increase safety in many environments by commonly color coding gas, steam, or chemical pipes; identifying hazardous work areas and walkways; and marking high voltage electrical lines and equipment.

Surface Preparation

The most important component of painting galvanized steel is to understand the galvanized coating’s characteristics as exposure to weather occurs. Galvanized steel can be divided into three categories: newly galvanized, partially weathered and fully weathered. Each type of galvanized steel must be prepared slightly differently, because the galvanized surface has different properties at each stage of weathering. No matter what the age of the galvanizing, the material should not be water or chromate quenched following galvanizing. These surface contaminants will interfere with paint adhesion. The ASTM Standard D6386 describes in detail the precautions and procedures required to properly prepare galvanized steel for painting.

Paint Selection

Beyond the need for surface preparation, the paint itself must be compatible with the galvanized coating in order to create a successful duplex system. Many types of paint and paint systems have been used quite well with galvanized steel. However, some types of paint will not adhere adequately to galvanized steel, or will only do so under restricted conditions. Ensuring a successful duplex system requires a paint system that encorporates a first coat that is fully compatible with the zinc substrate. The first coat serves as a “tie coat” or interface between the galvanized steel and the top coat. A keen understanding of the characteristics of all the types of paint that will be used is critical to this process. Each individual formulation of paint exhibits unique characteristics that can affect the suitability for use with galvanized steel. Because of this, only individual paint manufacturers can provide specific guidance on the use of their products. Contact paint manufacturers for specific information regarding the suitability of paint systems for use on galvanized steel.

AGA Publication

More detailed information on duplex systems can be found in the American Galvanizers publication titled “Duplex Systems — Painting Over Hot-Dip Galvanized Steel”.